Introduction

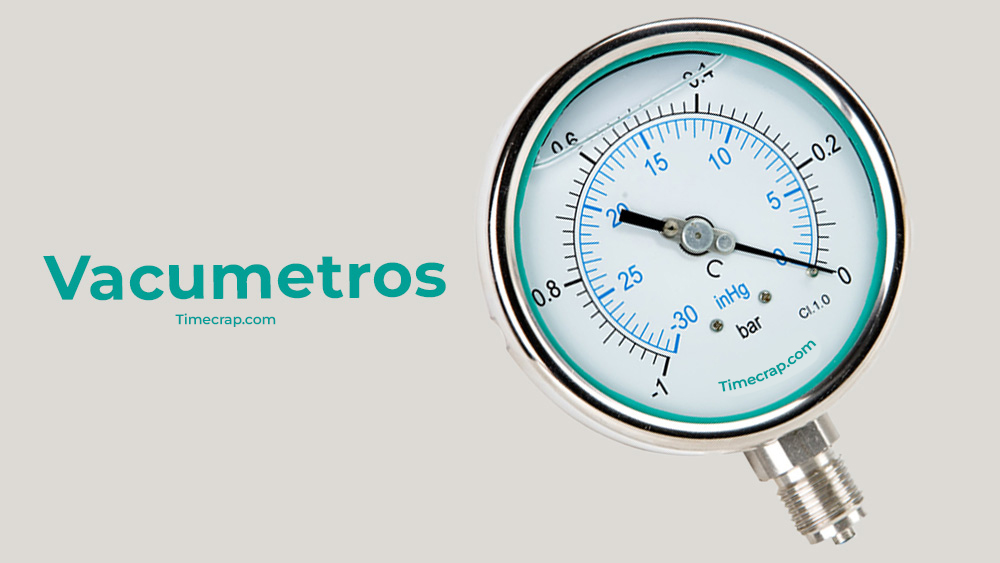

Vacumetros, moreover known as vacuum gages, are vital disobedience utilized over different businesses to degree and screen vacuum levels with unparalleled accuracy. These gadgets play an essential part in guaranteeing the effectiveness, quality, and security of forms in divisions extending from car fabricating to restorative applications.

How Vacumetros Work

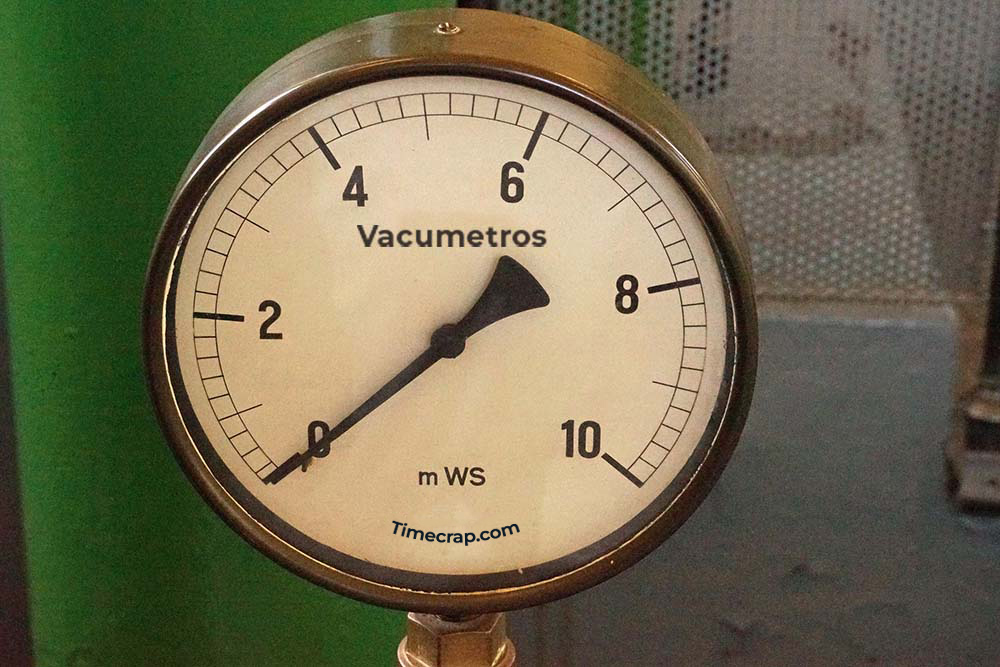

At their center, vacumetros work based on the guideline of measuring the weight contrast between the climatic weight and the pressure inside a vacuum. This is often through an arrangement of components, counting a sensor or gauge, which reacts to changes in weight. The component includes changing over these weight changes into electrical signals that are at that point shown as readings on the vacumetro.

The components of a vacumetro incorporate a sensor, flag preparing unit, and a show interface. The sensor identifies weight changes, the flag handling unit deciphers these changes, and the show interface presents the information in a user-friendly arrangement. Understanding this component is significant for increasing in value the precision and unwavering quality that vacumetros bring to different mechanical processes.

Sorts of Vacumetros

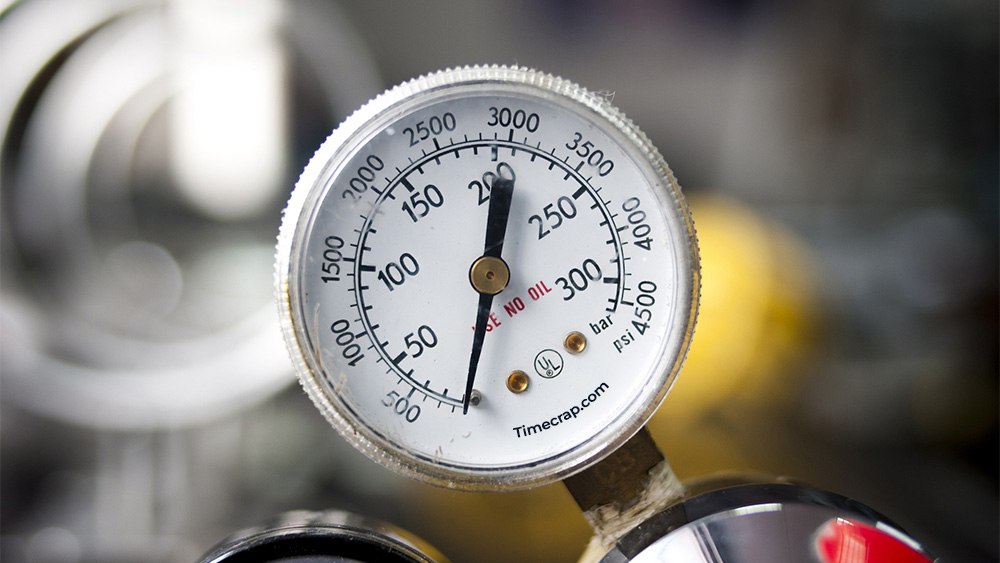

The advancement of innovation has driven to the advancement of distinctive sorts of vacumetros to cater to different industry needs. Analog vacumetros, with their conventional dial and needle display, offer a classic approach to weight estimation. On the other hand, advanced vacumetros use advanced innovation to supply exact advanced readings, frequently with extra highlights such as information logging and connectivity.

Convenient vacumetro have picked up notoriety due to their flexibility. These handheld gadgets empower on-the-go vacuum estimation, making them important for hands-on work and investigating. Understanding the subtleties of each sort permits businesses to select the vacumetro that best suits their particular requirements.

Applications of Vacumetros

The applications of vacumetro span a wide run of businesses, displaying their adaptability and importance. Within the car division, vacumetro are vital for observing and maintaining optimal vacuum levels in braking frameworks. Within the therapeutic field, vacumetro play a crucial part in forms like vacuum-assisted wound closure, guaranteeing exact and controlled conditions.

In mechanical forms, vacumetros contribute to the proficiency of assignments such as vacuum casting and bundling. Their capacity to degree and keep up vacuum levels guarantees the quality and consistency of conclusion items, making them a necessary portion of fabricating processes.

Focal points of Utilizing Vacumetros

The points of interest of consolidating vacumetro into mechanical forms are multifaceted. Accuracy and precision are vital, guaranteeing that vacuum levels are kept up inside indicated parameters. Real-time checking capabilities permit for prompt reaction to any deviations, anticipating potential issues and guaranteeing the smooth operation of processes.

Also, the information collected by vacumetro can be priceless for quality control and prepare optimization. The capacity to track vacuum levels over time provides experiences into the execution of hardware and permits for proactive upkeep, minimizing downtime.

Choosing the Correct Vacumetro

Selecting the correct vacumetro includes considering a few components. Businesses must assess the exactness prerequisites of their forms, the natural conditions in which the vacumetro will work, and any industry-specific benchmarks that must be followed to.

For illustration, in businesses where exactness is of most extreme significance, computerized vacumetro with high-resolution shows and progressed highlights may be favored. On the other hand, analog vacumetro may suffice for applications where a common run is acceptable.

Also Read: Zoomée: Redefining Virtual Connectivity

Upkeep Tips for Vacumetros

To guarantee the lifespan and exactness of vacumetro, standard upkeep is essential. Calibration, the method of altering the vacumetro to a standard reference, ought to be performed at regular intervals. The recurrence of calibration depends on components such as utilization, natural conditions, and industry standards.

Appropriate cleaning methods are similarly important. Dust and contaminants can influence the execution of the sensor and compromise the precision of readings. Normal reviews and cleaning, taking after producer rules, contribute to the ideal working of the vacumetro.

Challenges in Vacumetro Usage

Whereas vacumetro offer various benefits, they are not resistant to challenges. Natural components, such as temperature varieties and introduction to destructive substances, can affect their execution. Investigating issues, such as sensor breakdowns or show mistakes, may emerge and require opportune determination to preserve exact measurements.

Tending to these challenges includes a combination of preventive measures, customary support, and provoking investigating. Businesses depending on vacumetro must be proactive in distinguishing and moderating potential issues to guarantee ceaseless and reliable operation.

Future Trends in Vacumetro Technology

The future of vacumetros is checked by energizing mechanical progressions. Integration with the Internet of Things (IoT) is on the horizon, permitting vacumetro to be associated with systems for inaccessible observing and control. This network opens up conceivable outcomes for real-time information investigation, prescient support, and upgraded computerization in mechanical processes.

Headways in sensor innovation will advance and contribute to the exactness and affectability of vacumetro. Littler, more proficient sensors with made strides precision will make vacumetro indeed more flexible and dependable in a broader extent of applications.

Effect of Vacumetros on Efficiency

The effect of vacumetros on productivity is significant. In fabricating forms, vacumetros contribute to strides production rates by guaranteeing reliable and ideal vacuum conditions. This, in turn, leads to higher-quality conclusion items and reduced waste.

The effectiveness picks up and expands past fabrication to investigate and improve. Vacumetro play a pivotal part in tests and ponders where precise vacuum levels are required. Analysts can believe within the precision of vacumetro to preserve the vital conditions for their work, contributing to the headway of logical knowledge.

Case Studies

Analyzing case studies provides concrete illustrations of the positive effect vacumetro can have on different businesses. For occasion, within the car division, a case may highlight how the execution of vacumetro in brake frameworks is driven to progressed security and unwavering quality. Essentially, in the restorative field, a case ponders how vacumetro are necessary to imaginative therapeutic procedures.

These real-world illustrations offer bits of knowledge into the down to earth applications and benefits of vacumetro, making different industries make educated decisions about their adoption.

Client Testimonials

Understanding the encounters of businesses utilizing vacumetro gives profitable points of view. Tributes from professionals in car fabricating, therapeutic investigation, and other areas shed light on the day-to-day benefits of these instruments.

Clients regularly highlight the ease of utilization, unwavering quality, and the vital part vacumetro play in keeping up tall benchmarks in their operations. Such tributes serve as supports of vacumetro as vital apparatuses in exactness measurement.

Conclusion

In conclusion, vacumetro have ended up crucially disobedient over different industries, revolutionizing precision measurement and contributing to enhanced efficiency and quality. Their ability to monitor and maintain optimal vacuum levels is crucial for ensuring the success of processes in automotive, medical, and industrial settings.

As technology continues to advance, long term vacumetro looks promising with IoT integration and sensor improvements. Industries embracing these innovations stand to benefit from even greater precision, connectivity, and automation in their processes.

FAQs

What industries commonly use vacumetros?

Vacumetros are commonly used in industries such as automotive manufacturing, medical equipment production, and various industrial processes.

How often should a vacumetro be calibrated?

Regular calibration is essential to preserve accuracy of vacumetros. The frequency depends on usage and industry standards.

Are digital or analog vacumetros more accurate?

Both digital and analog vacumetros can provide accurate readings. The choice depends on specific requirements and user preferences.

Can vacumetros be used for research purposes?

Yes, vacumetros are widely used in research settings for their precision in measuring vacuum levels.

What is the average lifespan of a vacumetro?

The average lifespan of a vacumetro depends on usage and maintenance. Regular calibration and proper care can extend its lifespan significantly.

Also Checkout : Turtle Box Speaker: Your Fun Sound Buddy